Smart ’turn-key’ solutions in special machine construction for assembly and welding fixtures are the specialty of Fuchs Werkzeug- und Maschinenbau GmbH. From design to production and assembly, the Lebach-based company supplies high-quality machines and assemblies for the automotive industry, the agricultural sector, construction machinery and the defense industry. Mapping complex joining sequences or initial situations with a simple fixture that is easy to handle is the passion and special art of the experts from the Saarland.

“To build our fixtures, we usually use stainless steel sheets, which we cut into suitable shapes by laser or waterjet. The fact that this produces burrs and sharp edges is in the nature of things. In order to reduce the risk of injury during subsequent handling of the assemblies and not to impair their functionality, deburring is one of our standard processes. Also, very strong edge rounding is often necessary on the sheet metal parts to meet our quality requirements,” says David Welter, production planner at Fuchs Werkzeug- und Maschinenbau GmbH.

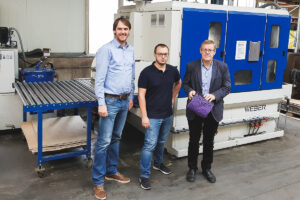

Partnership for record-breaking results (from left): Marc Böck, Managing Director of boeck GmbH, and David Welter, Production Planner at Fuchs Werkzeug- und Maschinenbau GmbH.

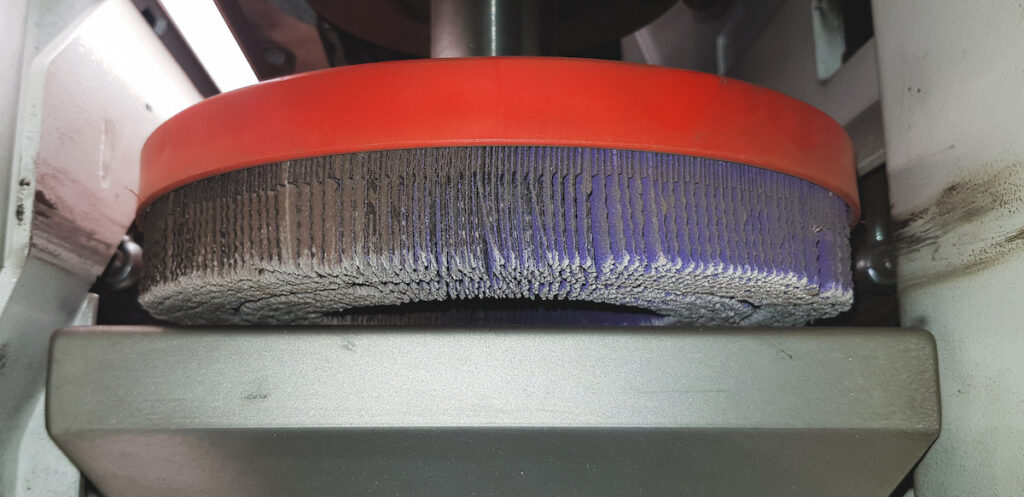

Thanks to the three machining stations – a grinding device followed by four oscillating brushes – various work steps such as deburring and edge rounding are possible in one pass – and at high speed. “We didn’t want to simply convert manual machining into a machine process, but our focus was also primarily on achieving very strong edge rounding within the shortest possible time while maintaining a high working speed or feed rate,” explains David Welter. “The Q-FIN machine is perfect for these requirements. We found the right tools to deliver top performance in this world of extremes in boeck’s HERO deburring discs.”

This is no coincidence, because the team of experts around engineers Marc and Jochen Böck developed the HERO deburring discs for exactly such challenges. “Customized tool solutions for sheet metal deburring, from slag removal and pre-grinding to deburring, rounding, oxide removal and surface finishing, are our passion – from development to production. Self-developed machines with a high degree of automation for the production of tools are an essential part of our structured high-performance processes, which guarantee the highest quality and short delivery times. With the high demands that Fuchs places on the quality and edge rounding of the sheet metal parts, it was quickly clear to us that only HERO deburring discs would come into question here,” says Marc Böck, Managing Director of boeck GmbH.

The Q-FIN grinding and deburring machine is ideally suited for the high demands at Fuchs Werkzeug- und Maschinenbau.

Extreme kantafronding in de kortst mogelijke tijd?

Klik hier om onze HERO-producten voor Q-FIN machines te ontdekken.