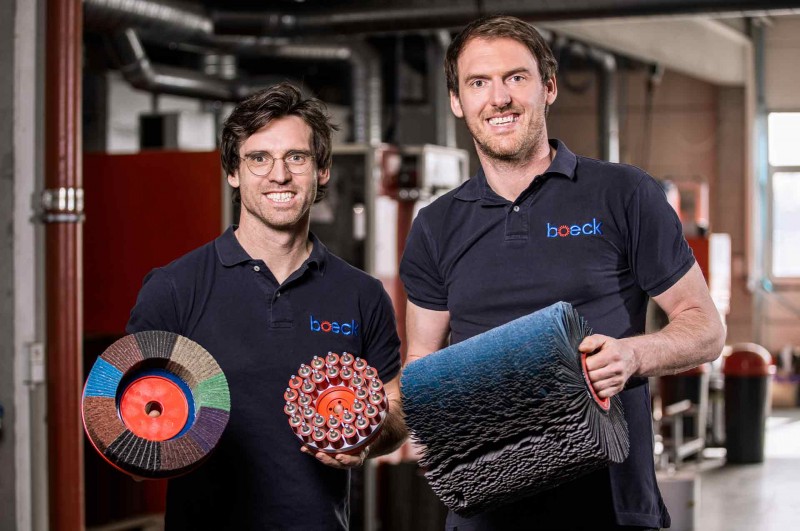

BOECK - ENTHUSIASTS IN TECHNOLOGY

“Impossible” is a word which is not in our vocabulary: Once you have met our company owners in person, you realise: Marc and Jochen Böck are two engineers who are certainly not just your average “manufacturers”.

THE PERFECT TOOL!

boeck develops both economical standard solutions and sophisticated customised ones, tailored to the individual needs of our customers. This is based on the identification, assessment, development as well as enhancement and integration of the latest product and production technologies, setting new standards.

A deep understanding of application technology forms the basis for optimum process parameters and safeguards our customers’ economic processes. Based on scientific methods, our tool solutions are permanently enhanced further and guarantee state-of-the-art processes are applied. Looking for, choosing and assessing the latest technologies as well as their daily application, always pushing boundaries, ensures efficiency and sustainability. Of course always providing the shortest of possible lead times.

OUR BENEFITS

EFFICIENCY THROUGH INNOVATION

Significant added value for our customers is at the centre of all our thoughts and deeds. And for this reason, we will always apply a perfectionist approach, pushing technological boundaries.

KNOW-HOW AND ADVICE

Our customers benefit from our strong advisory and application expertise. This know-how ensures optimum competitiveness based on maximum performance processes in every production facility.

FAST SHIPMENTS

Almost all our tools are shipped the same day they are ordered. Because downtime is not an option.

HISTORY

2021

1 JULY 2021

Founding of boeck Inc. (USA)

MARCH 2021

FT 1000 – boeck is one of the fastest-growing companies in Europe

2020

AUGUST 2020

Wood processing tools manufacturing facility launched

2019

DECEMBER 2019

Production space doubles

2018

MARCH 2018

Another patent applied

JANUARY 2018

Introduction of new deslagging brush

2017

APRIL 2017

Production space doubles

2016

OCTOBER 2016

First patent applied

2015

MARCH 2015

Enhanced product development of multi-row deburring tools

2014

OCTOBER 2014

Presentation of the latest generation deburring rollers and development of rapid clamping systems

2013

14 OCTOBER 2013

Our first product sold – our deburring disc QUICK 115

JULY 2013

Founding of boeck GmbH