Powerful deburring tools

Consumer electronics and computer and communications technology are among the booming markets of the future. This not only increases the

You do not want to miss any news and you’re looking for information on the topics of slag removal, pre-grinding & deburring, deburring & edge-rounding, oxide removal and finish-grinding. Here we keep the most important news and information ready for you.

Consumer electronics and computer and communications technology are among the booming markets of the future. This not only increases the

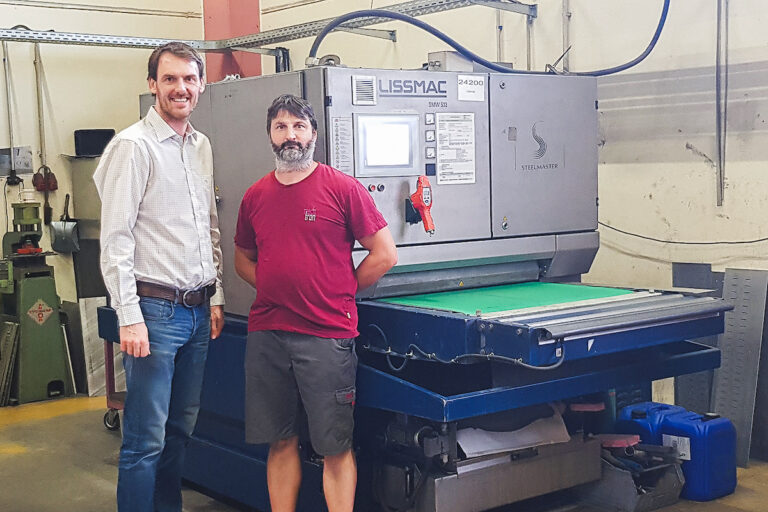

Deburring is an important step in metal processing. However, only a few have deep detailed knowledge in this special field.

If you want to reduce costs in production without sacrificing quality, you often have only one set screw: shorter setup

Strong edge rounding, long service lives, good performance Elements for interior fittings and air conditioners for railway technology, ceiling elements

Consumer electronics and computer and communications technology are among the booming markets of the future. This not only increases the

Deburring is an important step in metal processing. However, only a few have deep detailed knowledge in this special field.

If you want to reduce costs in production without sacrificing quality, you often have only one set screw: shorter setup

Strong edge rounding, long service lives, good performance Elements for interior fittings and air conditioners for railway technology, ceiling elements

The newsletter for real sheet metal workers! Subscribe to the free boeck newsletter for news & knowledge about sheet metal working topics.

boeck GmbH – Your tool for deburring sheet metal! We produce customized tool solutions for your sheet metal deburring process steps from slag removal, pre-grinding, deburring, rounding, oxide removal to finish grinding. MADE IN GERMANY!

boeck GmbH

Ludwigstraße 8

89340 Leipheim

Germany

YOUR TOOL FOR DEBURRING SHEET METAL!

When you choose the BOOST option, your tool will be equipped with Cubitron™ II abrasive. These ceramic grains are sharp, uniform and have the shape of small triangles. This enables greater stock removal, a higher feed rate and more productivity.