Showing all 2 results

Deburring and rounding of sheets with highest feed speed and hugest edge-rounding with deburring discs, deburring wheels and deburring blocks

Sheet metal must be deburred and rounded to reduce the risk of injury at sharp sheet metal edges, to prime the surface for subsequent coatings (powder coating, galvanizing, anodizing, etc.) or to create edge radii of up to 2 mm, as is now required by standards (e.g. DIN EN 1090). For this purpose, primary and secondary burrs must first be removed and the edge rounded at the same time.

Deburring and edge-rounding is performed by flexible abrasive tools with high adaptability to internal and external contours such as radii, bores and cutouts. The corresponding deburring tools are used on manual machines as well as grinding and deburring machines. The latter have, for example, oscillating or rotating units for uniform processing of the edges.

The design options of the deburring discs, deburring wheels and deburring blocks are manifold. Depending on the range of workpieces, the tools can be equipped with various fillings. This makes it possible to achieve the highest feed rate, the hugest edge rounding and, at the same time, perfect surfaces.

This video shows how the boeck deburring tools work:

Deburring and edge-rounding of sheet metal workpieces can be performed with various tools. The deburring tools are available in the following forms:

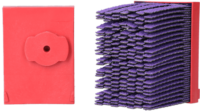

- Deburring block

- Deburring segment

- Deburring disc

- Deburring wheel

All boeck disc tools for deburring and edge-rounding are available with the QUICK quick-release system.

Deburring and edge-rounding tools are available for all machine types in various dimensions and different mounts.

| Arku | Authentec | Boere | Bütfering |

| Costa | DMC | EMC | Ernst |

| Famak | Finishline | Fladder | Gecam |

| Heesemann | Houfek | Jonsen | Kuhlmeyer |

| Lissmac | Loeser | Loewer | Madora |

| Mc Talleres | Metalbrus | Midwest | Ming Ping |

| Murata | Niederberger | NS Máquinas | Peitzmeier |

| Pola e massa | Q-Fin | RWT | Salida |

| St. Link | Telefoncular | Timesavers | Tripuris |

| VG Machine | Viet | Weber | Wöhler |

| Wolters |

Grinding stars can be used to efficiently deburr tubes & profiles

After cutting tubes and profiles, sharp cut edges are often unavoidable. Even with the most advanced cutting processes, sharp cut edges will often occur. In order to reduce the risk of injury or to ensure assembly capability, this burr must be removed. With the help of our grinding stars consisting of abrasive layers, protruding burrs can be ground off.

The boeck grinding stars can be used on stationary or hand-held deburring machines. With the help of various slits, the grinding star engages in the tube or profile and deburrs or even rounds the workpiece.

Advantages of boeck grinding stars:

- Deburring & rounding in the shortest possible processing time

- Material is removed instead of just reshaped

- No grinding necessary thanks to circular outer contour

- Sealed cutting edges due to lasered abrasive cloth