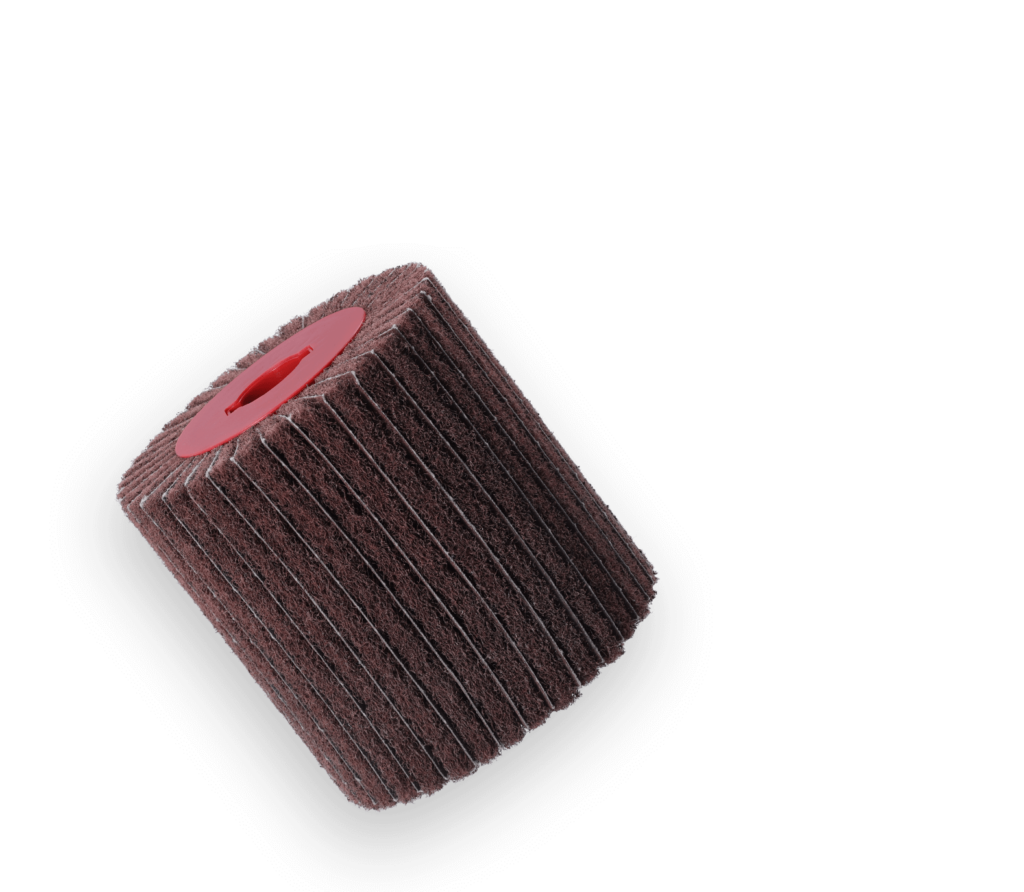

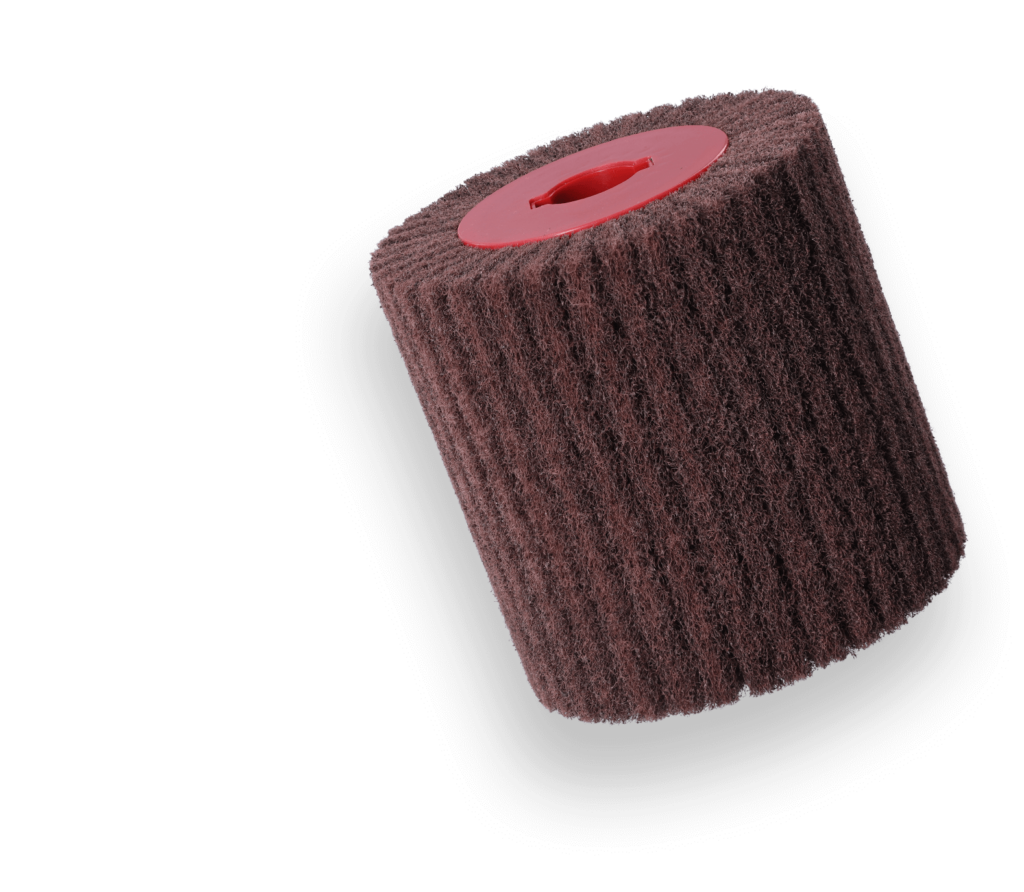

FLAP WHEELS

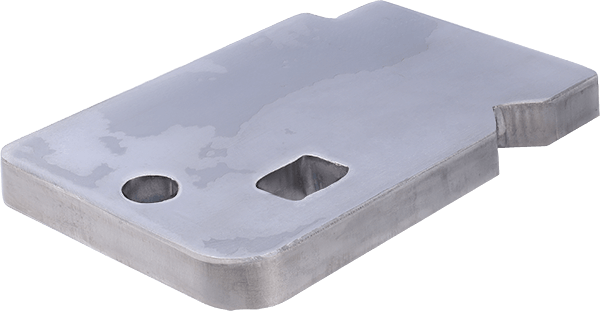

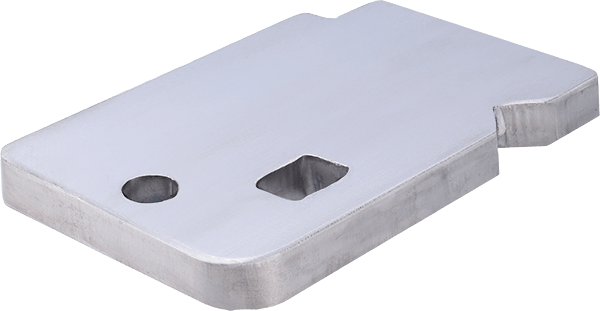

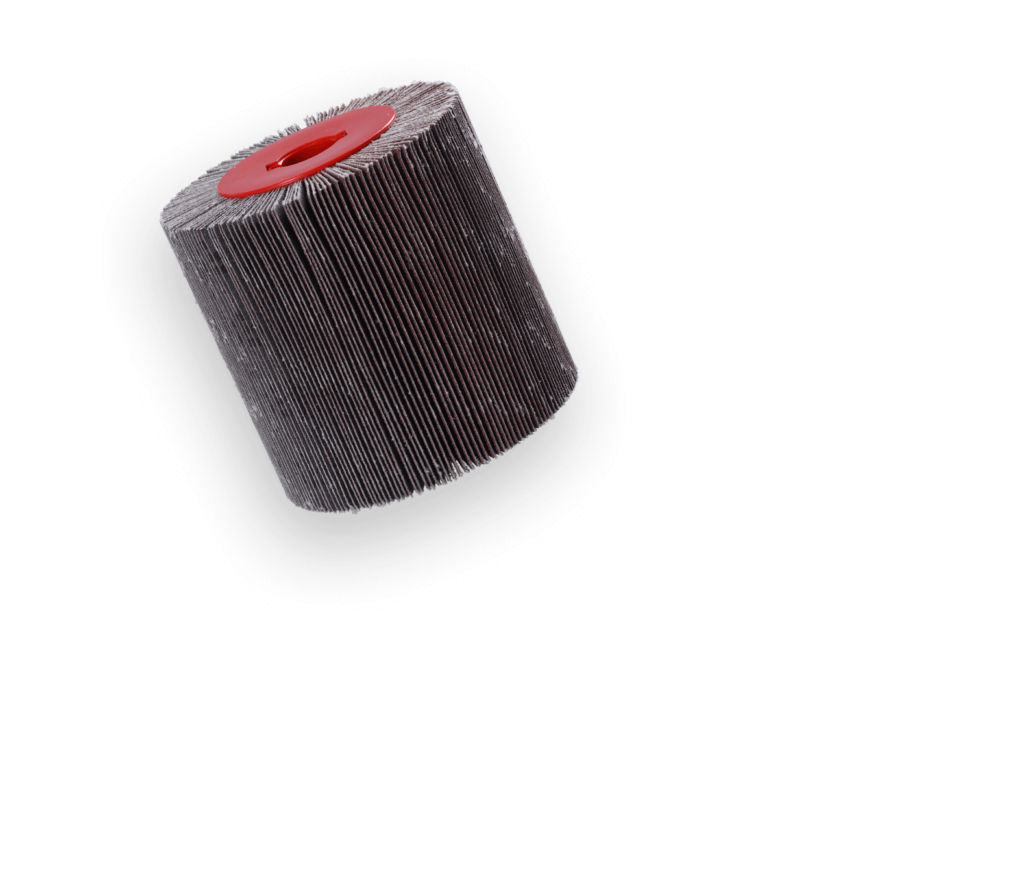

Abrasive flap wheels, also known as satin finishing wheels or drum wheels, are the perfect tool for grinding and finishing extremely contoured workpieces with satin finishing machines. Due to their flexible lamella layout, they effortlessly adapt to curves and edges, resulting in a uniform metal finish.

Utilizing flap wheels

Flap wheels, also known as satin finishing wheels, are some of the most versatile tools to have on hand when sheet metal working. Their flexible abrasive flaps made from abrasive cloth and/or non-woven fleece make them very effective for grinding or finishing irregularly shaped metal, wood or plastic workpieces. They can be mounted on all common satin finishing machines (drum grinders, burnishing machines).

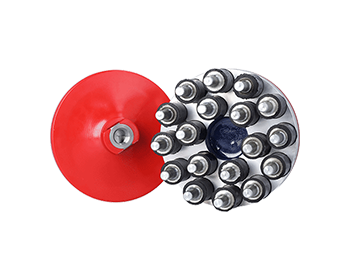

At boeck, we produce three kinds of satin finishing wheels: lamellar grinding wheels for grinding, non-woven fleece wheels for satin finishing, and combination wheels. We offer various sizes, mounts and abrasives, such as aluminum oxide, zirconia alumina, ceramic and Cubitron™ II.

OUR TOOLS FOR satin finishing machines

Why opt for flap wheels?

The uniform lamella arrangement on boeck flap wheels offers many advantages when working on different materials. Individual flap construction promotes even wear across the entire wheel for consistent performance and maximum product life. We recommend boeck satin finishing wheels for applications such as:

- Light pre-grinding and deburring.

- Surface grinding.

- Finishing and polishing.

VERY FINE

FINE

MEDIUM

satin finishing wheels in action

OUR PRODUCTS ARE COMPATIBLE WITH COMMON MACHINE MANUFACTURERS

Arku | Authentec | Boere | Bütfering | Costa | DMC | EMC | Ernst | Finishline | Fladder | Flex | Gecam | Heesemann | Houfek | Jonsen | Kuhlmeyer | Lissmac |

Loeser | Loewer | Madora | Mc Talleres | Metabo | Metalbrus | Midwest | Ming Ping | Murata | Niederberger | NS Máquinas | Peitzmeier | Pola e massa | Q-Fin | RWT | Salida | St. Link | Timesavers | Tripuris | VG Machine | Viet | Weber | Wöhler | Wolters

the newest technologies

boeck GmbH develops and manufactures the latest technologies for sheet metal processing, including grinding on satin finishing machines. Tool development is driven both by the requirements of our customers and by rigorous in-house testing. This dual approach allows us to develop a deep understanding of the influencing factors and their interactions within the sheet metal working process, which we translate into effective solutions. As a result, you benefit from tools that are perfectly tailored to your needs, as well as expert know-how regarding optimal process parameters.

Our tools are proudly MADE IN GERMANY, crafted by highly qualified personnel using the latest, highly integrated machining technologies. In terms of production objectives, we achieve maximum efficiency, particularly through the automation and continuous digitization of administrative and technical processes.

We are committed to ensuring that our customers benefit from the highest quality and most effective tools, customized in the shortest possible time.

OUR CUSTOMERS' SUCCESS

Saving processing time

Reduce processing times and make your process more cost-effective by switching to satin finishing wheels customized to your needs.

versatile processing on a single machine

Satin finishing wheels are available in countless variations, suited to multiple materials and highly contoured workpieces.

Optimization of the deburring process

Our mission is optimizing the entire process chain, from slag removal to finish grinding. We apply the latest know-how and production technologies to our tools.

YOUR CONTACT PERSONS

MARC BÖCK

Dipl.-Ing. (FH) Dipl.-Kfm. (FH)

CEO

ANJA BERSCHEIT

M.Sc.

Head of automation & quality