Grinding and edge breaking wood with tools from boeck

We aim to improve and streamline your entire woodworking process with our wide range of tool solutions. Grinding and edge breaking ensures that the rough surface and edges of the workpiece are prepared for further processing steps. No matter which machine or material you work with, at boeck you will find unique tools for your process.

Grinding and edge breaking

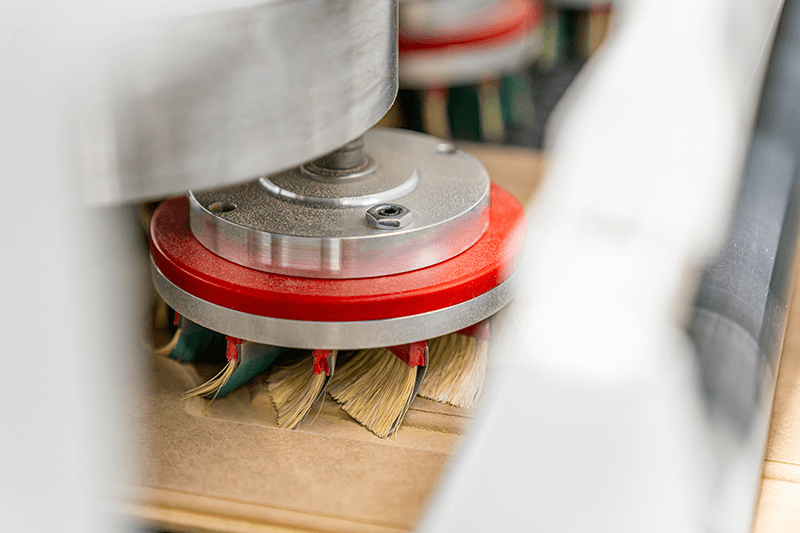

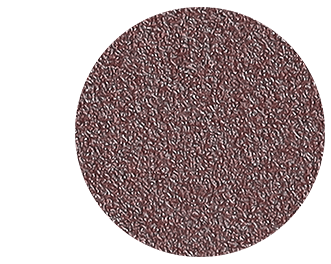

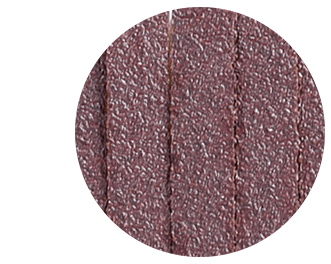

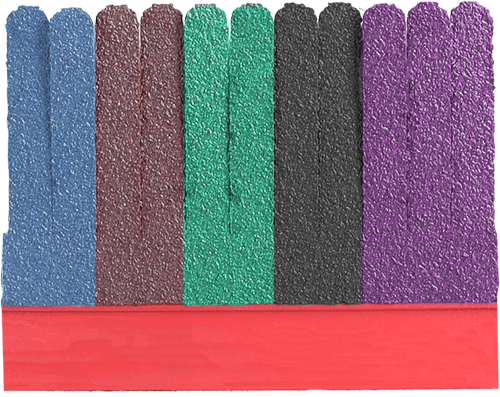

The quality of the surface plays a central role in wood processing. This is why the grinding and edge-breaking steps are of great relevance. Not only a pleasant feel is important, but also the preparation for further work steps, e.g. for varnishing. To achieve the desired surface quality, the use of boeck grinding brush discs is recommended. Depending on the facing material, they treat the surface with a correspondingly strong or weak grinding action.

before/after

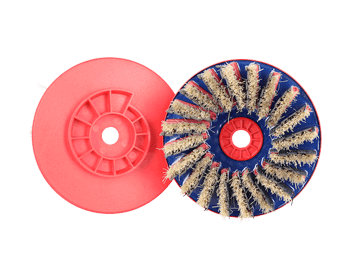

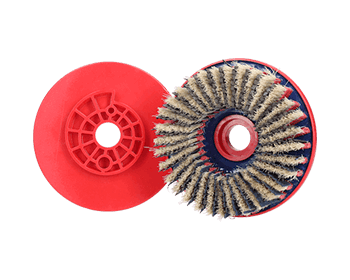

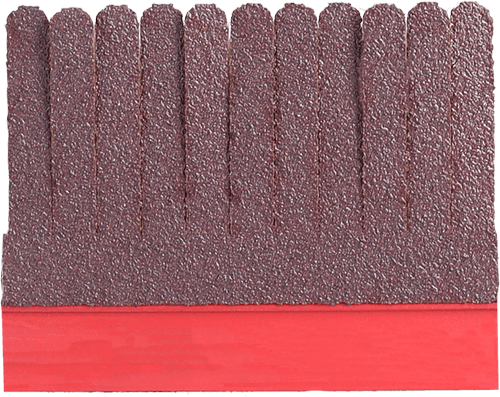

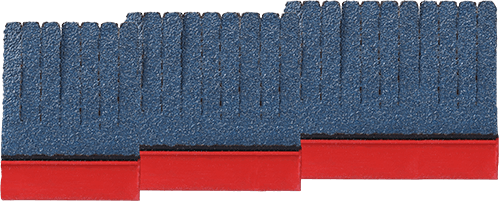

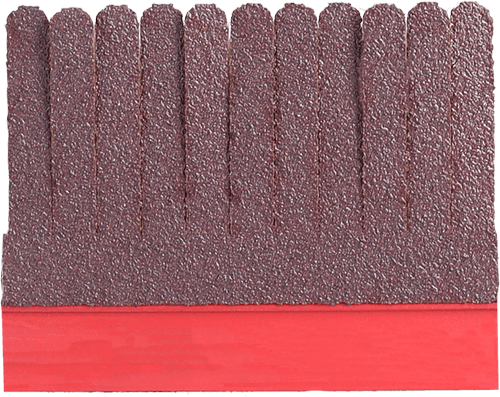

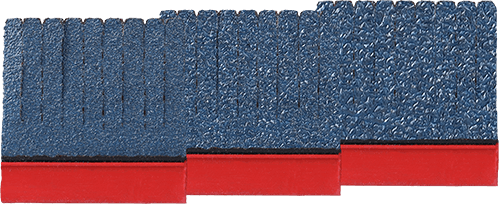

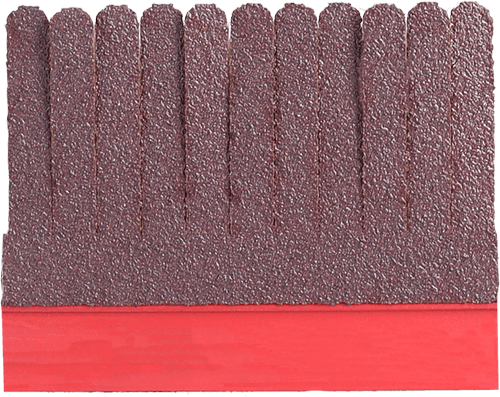

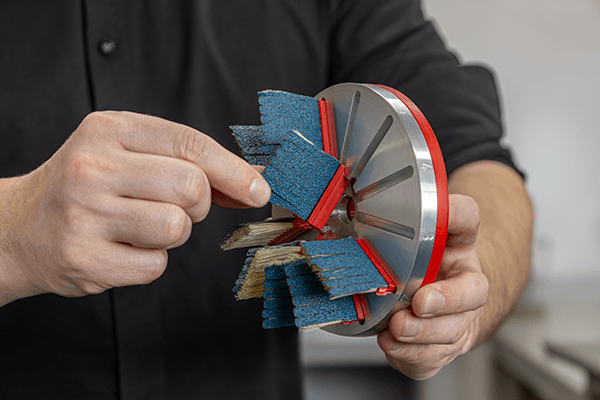

Grinding brush discs

Our grinding brush discs are ideal for grinding and edge-breaking wood! They achieve a low contact pressure on the workpiece and therefore ensure a smooth surface and ideally rounded edges.

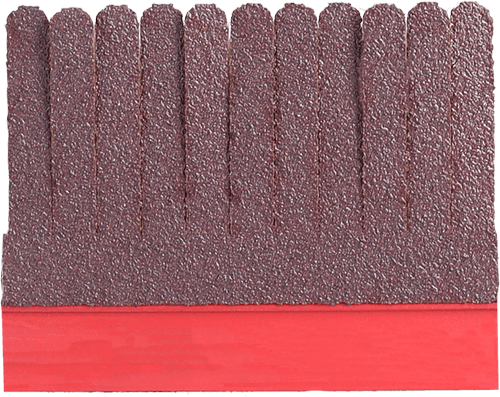

Due to the open arrangement of the abrasive cloth flaps, the fill is very flexible and results in a high adaptability of the tool to the contour. Together with the tampico fiber fill, they still provide sufficient grip to ensure adequate contact pressure on the workpiece. Boeck grinding brush discs are available for stationary and manual machines.

YOU CHOOSE:

Height

Height

Length

Length

Grit

Grit

Slit pattern

Slit pattern

Edition

BLUE EDITION

BROWN EDITION

GREEN EDITION

GREY EDITION

PURPLE EDITION

boeck brush holder

The boeck brush plate holder allows the brushes to be changed quickly and easily with minimal effort. However, in order to maintain a perfect and uniform grinding pattern, it is advisable to change only every second brush after wear. This alternating change ensures that the aggressiveness of the brushes remains constant with the same machine settings. If all the brushes are changed at the same time, the grinding action will be too aggressive at the beginning of use and will become less aggressive over time. The numbering on the side of each holder slot helps to keep track.

BENEFITS WITH BOECK

Your tool for Woodworking! Boeck excels at making the seemingly impossible come true, maintaining focus and driving progress with enthusiasm.

We offer economical standard solutions and sophisticated individual solutions according to customer requirements. Our principle of action is to evaluate, develop and integrate the latest products and manufacturing techniques in order to set new standards and to develop and manufacture the right tools for our customers.

OUR PRODUCTS ARE COMPATIBLE WITH MOST MACHINE MANUFACTURERS

Arku | Authentec | Boere | Bütfering | Costa | DMC | EMC | Ernst | Famak | Finishline | Fladder® | Gecam | Heesemann | Houfek | Jonsen | Kuhlmeyer | Lissmac | Loeser | Loewer | Madora | Mc Talleres | Metalbrus | Midwest | Ming Ping | Murata | Niederberger | NS Máquinas | Peitzmeier | Pola e massa | Q-Fin | RWT | Salida | St. Link | Telefoncular | Timesavers | Tripuris | VG Machines | Viet | Weber | Wöhler | Wolters

OUR CUSTOMERS' BENEFITS

SAVING PROCESSING TIME

Reduce processing time and improve process economics by switching to tools that meet your needs.

KNOW-HOW AND CONSULTING

Our customers benefit from our high level of consulting and application expertise. This know-how ensures optimal competitiveness based on high-performance processes at every production site.

Optimization of the sanding process

Our task is to optimize the entire process chain from sanding and pore opening to cleaning and polishing. We use the latest know-how and state-of-the-art production technologies for our tools.

YOUR CONTACT PERSONS

MARC BÖCK

Dipl.-Ing. (FH) Dipl.-Kfm. (FH)

CEO

ERICH LIEDEL

Dipl.-Ing. (FH)

Plant manager