Werkzeuge von boeck für Q-Fin Maschinen

×

×

boeck at the THU Career Day 2024! We develop and produce high-quality tools for the entire sheet metal deburring process and are always on the lookout for new talent. Are you interested? Then stop by our stand!

THU KARRIERETAG 2024!

- 16. October, 2024

- THU Campus

- Campus Prittwitzstraße 10, 89075 Ulm

On October 16, 2024 the THU Career Day will take place and of course we will be there.

At the THU Career Day, companies have the opportunity to get in touch with students from all technical disciplines. boeck GmbH will also be there! We are always happy to meet people interested in internships, working student jobs or completing a Bachelor’s/Master’s thesis. With us you will find everything from simple to complex tasks, a strong, motivated team and a lot of fun! Do you have what it takes to be a real sheet metal worker? Then come by our stand at the THU Careers Day and find out more about boeck GmbH!

Benefits with boeck

Self-improvement

You can expect good development opportunities in a varied work environment.

MODERN WORKING ENVIRONMENT

You will work with the latest technologies in an innovative, fast-growing company.

great WORKING ATMOSPHERE

You can expect an open-minded team and a lot of fun – outside the office, too.

Here is a little impression about us!

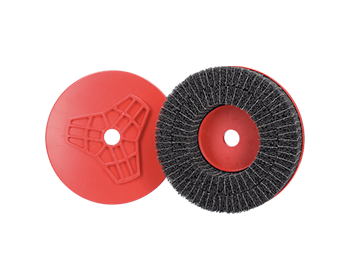

TOOLS BY BOECK

Your tool for deburring sheet metal! We realize economical solutions for the sheet metal deburring process chain. These include deslagging brushes, deburring discs, blocks, wheels, abrasive belts, oxide brushes and non-woven abrasive belts. Get to know us more at THU Karrieretag 2024!

DIRECTIONS

Internship, bachelor and master theses

OUR CUSTOMERS' BENEFITS

SAVINGS IN PROCESSING TIMES

Processing times can be reduced by tailoring the tools to fit customers' machines and projects. One customer application shows, that 50% processing time can be saved during deburring.

MAXIMIZING EDGE ROUNDING

The latest generation of deburring discs with a new arrangement and slot structure of the grinding flaps maximizes the grinding active stocking and increases the removal at the sheet edge as well as the performance of deburring machines.

optimizing the sheet metal processing chain

Our customers benefit from our distinctive consulting and application expertise. This know-how guarantees maximum competitiveness through high-performance processes in every production.

OUR PRODUCTS ARE COMPATIBLE WITH MOST MACHINE MANUFACTURERS

Arku | Authentec | Boere | Bütfering | Costa | DMC | EMC | Ernst | Famak | Finishline | Fladder® | Gecam | Heesemann | Houfek | Jonsen | Kuhlmeyer | Lissmac | Loeser | Loewer | Madora | Mc Talleres | Metalbrus | Midwest | Ming Ping | Murata | Niederberger | NS Máquinas | Peitzmeier | Pola e massa | Q-Fin | RWT | Salida | St. Link | Telefoncular | Timesavers | Tripuris | VG Machines | Viet | Weber | Wöhler | Wolters

YOUR CONTACT PERSONS

MARC BÖCK

Dipl.-Ing. (FH) Dipl.-Kfm. (FH)

CEO

ANJA BERSCHEIT

M.Sc.

Head of automation & quality