Showing 1–12 of 16 results

Metallic bare cut edges for your sheet metal!

Workpieces cut with oxygen exhibit oxide layers at the cut edges. These "dark layers" pose a risk of adhesion, particularly for subsequent coating processes. For example, they can cause the powder coating or the zinc coating to flake off.

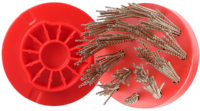

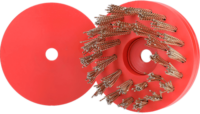

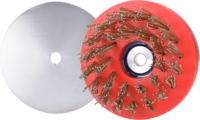

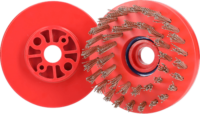

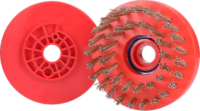

The oxide layer is removed with oxide brushes or oxide wheels. Oxide brushes in disc form are designed with a specially developed wire trim in an innovative multi-row arrangement. Oxide wheels consist of mounted spring assemblies. The trim of the tools is flexible, follows the contours of the workpiece and achieves bare metal edge surfaces.

This video shows how boeck oxide tools work:

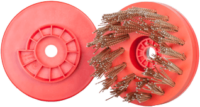

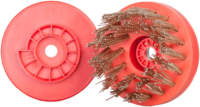

If deburring and oxide wheels are used simultaneously on a machine with a wheel unit, the wear of the deburring wheels must be compensated by the infeed. This means that the diameter of the oxide wheel must also be adjusted. The adaptive oxide wheels have been developed especially for this application. The adaptive wheel is equipped with a new rotating mechanism and the diameter can be changed by up to 25% in a very short time. This allows the tools to be used under optimum infeed conditions, the oxide layer to be removed and the edges to be deburred and rounded at the same time.

This video demonstrates the advantages of the adaptive oxide wheel:

All boeck disc tools for oxide removal are available with the QUICK quick-release system.

Oxide tools are available for all types of machines in different dimensions and different mounts.

| Arku | Authentec | Boere | Bütfering |

| Costa | DMC | EMC | Ernst |

| Famak | Finishline | Fladder | Gecam |

| Heesemann | Houfek | Jonsen | Kuhlmeyer |

| Lissmac | Loeser | Loewer | Madora |

| Mc Talleres | Metalbrus | Midwest | Ming Ping |

| Murata | Niederberger | NS Máquinas | Peitzmeier |

| Pola e massa | Q-Fin | RWT | Salida |

| St. Link | Telefoncular | Timesavers | Tripuris |

| VG Machine | Viet | Weber | Wöhler |

| Wolters |