DEBURRING DISCS BY BOECK

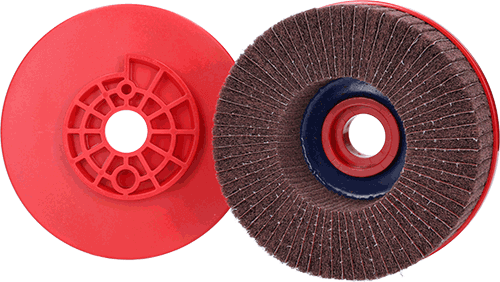

Deburring discs are used to remove primary and secondary burrs and to round sheet metal edges. They can be equipped with various abrasives suitable for steel, stainless steel, aluminum, galvanized, and foil-coated sheets. In our extensive range, you will find the right tools to optimize the deburring process for your sheet metal.

Deburring and edge-rounding

Deburring and edge rounding of metal parts are among the first steps after cutting. During this process, primary and secondary burrs are removed, and edges are rounded. Highly flexible tools are used, allowing easy access to holes and cut-outs in the sheet metal.

Our tools are specifically designed for deburring applications and offer a wide variety of abrasive options. We provide the right materials for deburring, edge rounding, and surface grinding to suit every workpiece.

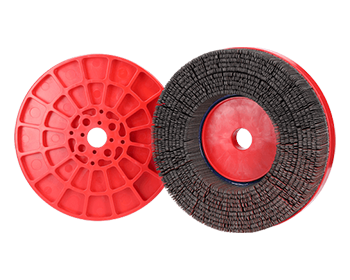

boeck deburring discs

Standard, professional, or HERO?

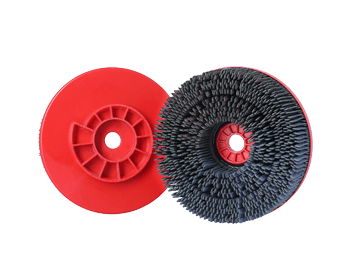

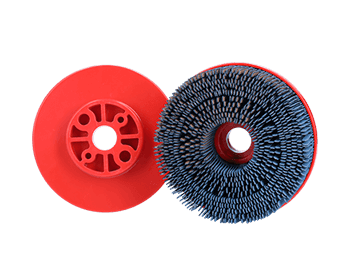

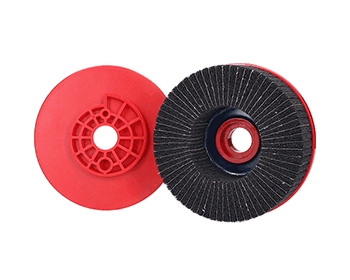

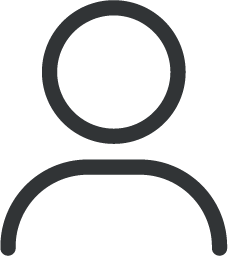

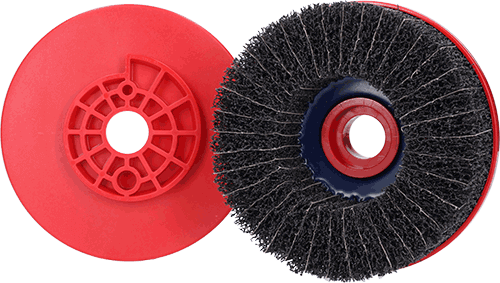

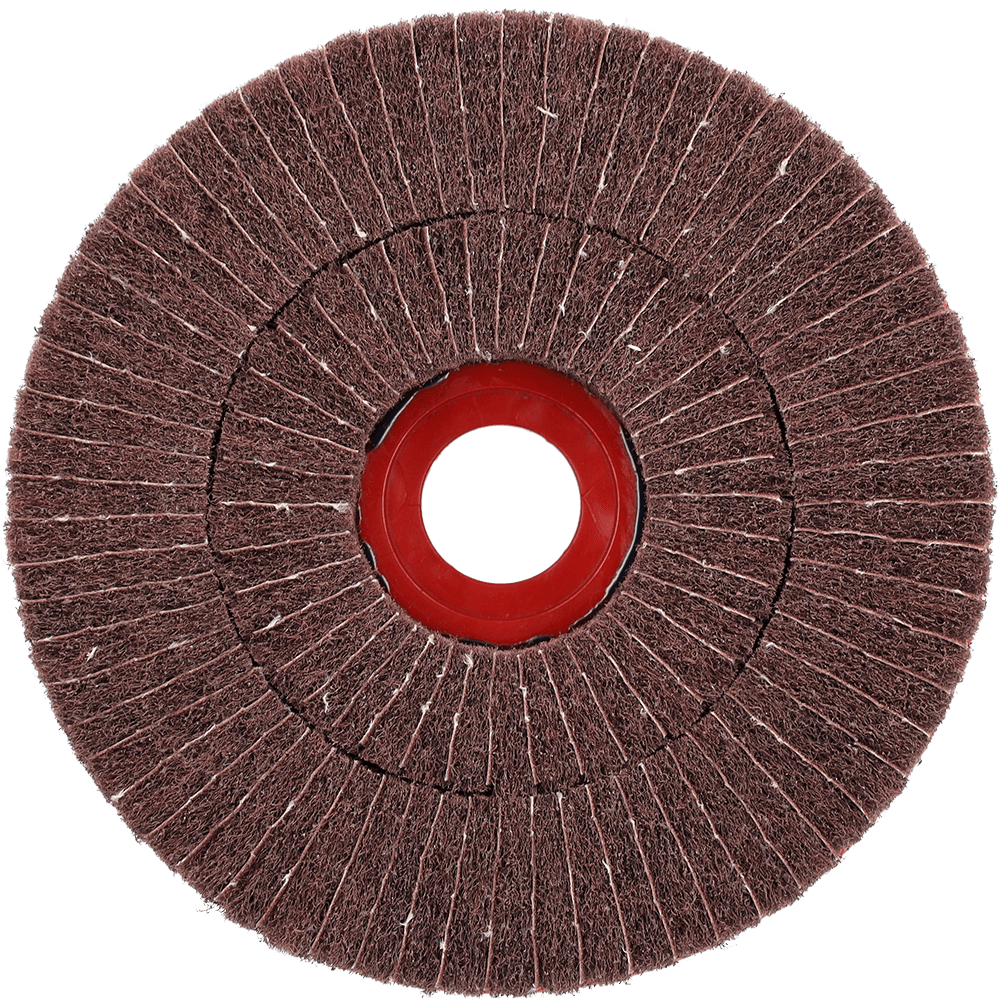

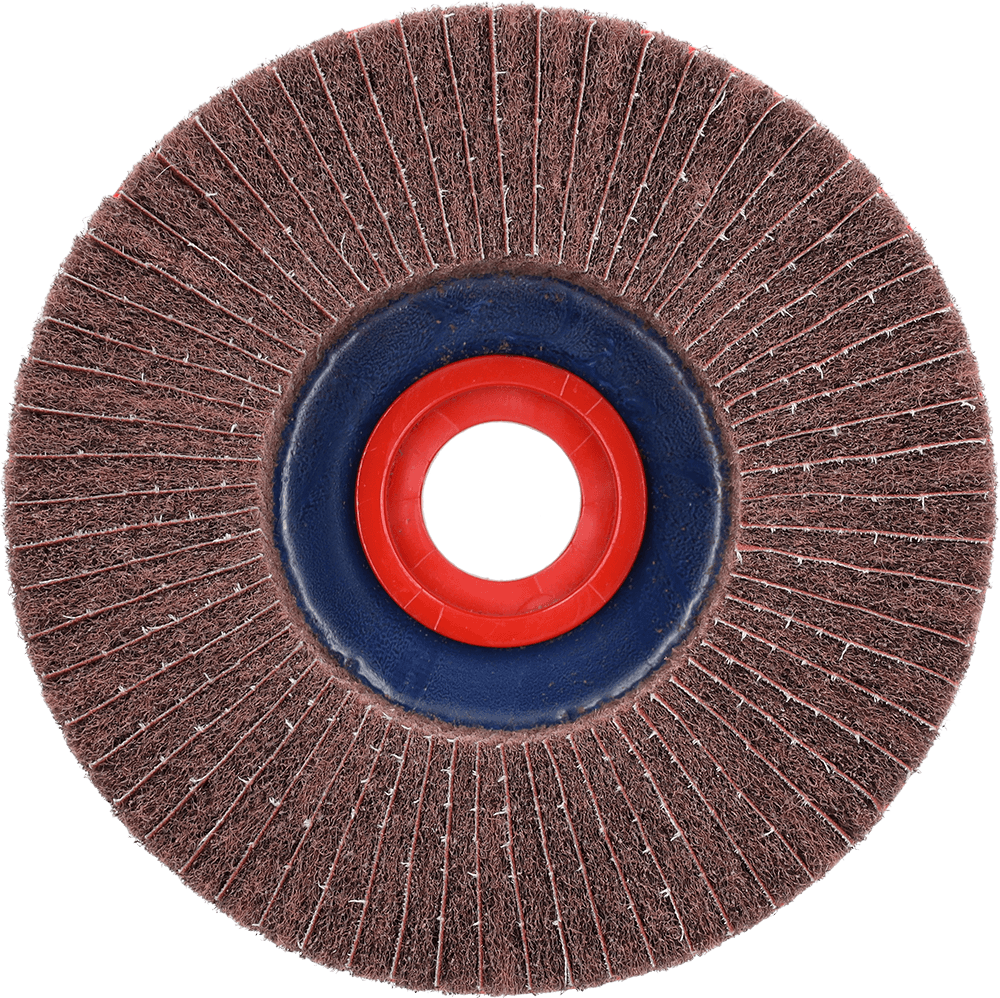

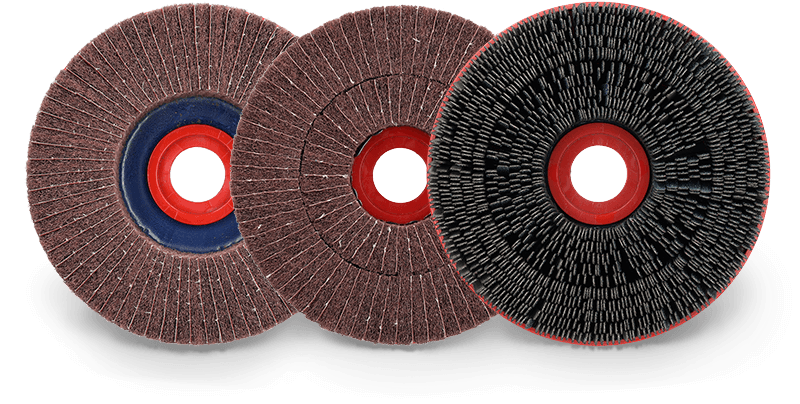

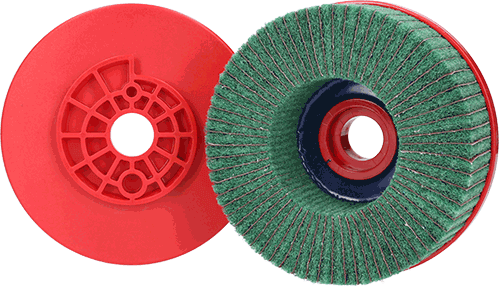

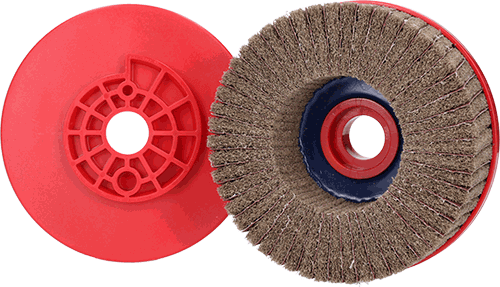

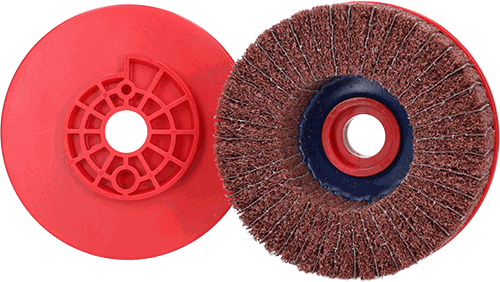

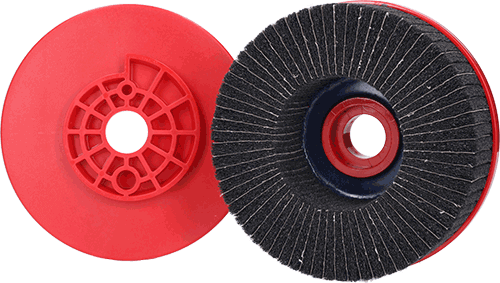

Boeck deburring discs are available in three editions, ensuring you find the perfect tool for your requirements. The STANDARD deburring discs feature a single-row rim. In contrast, the PROFESSIONAL deburring discs include a double-row abrasive coating, providing a larger contact surface, more active abrasive flaps, and a balanced contact pressure ratio achieved through the alignment of the outer and inner rings. Both the STANDARD and PROFESSIONAL versions combine cloth and non-woven abrasive flaps.

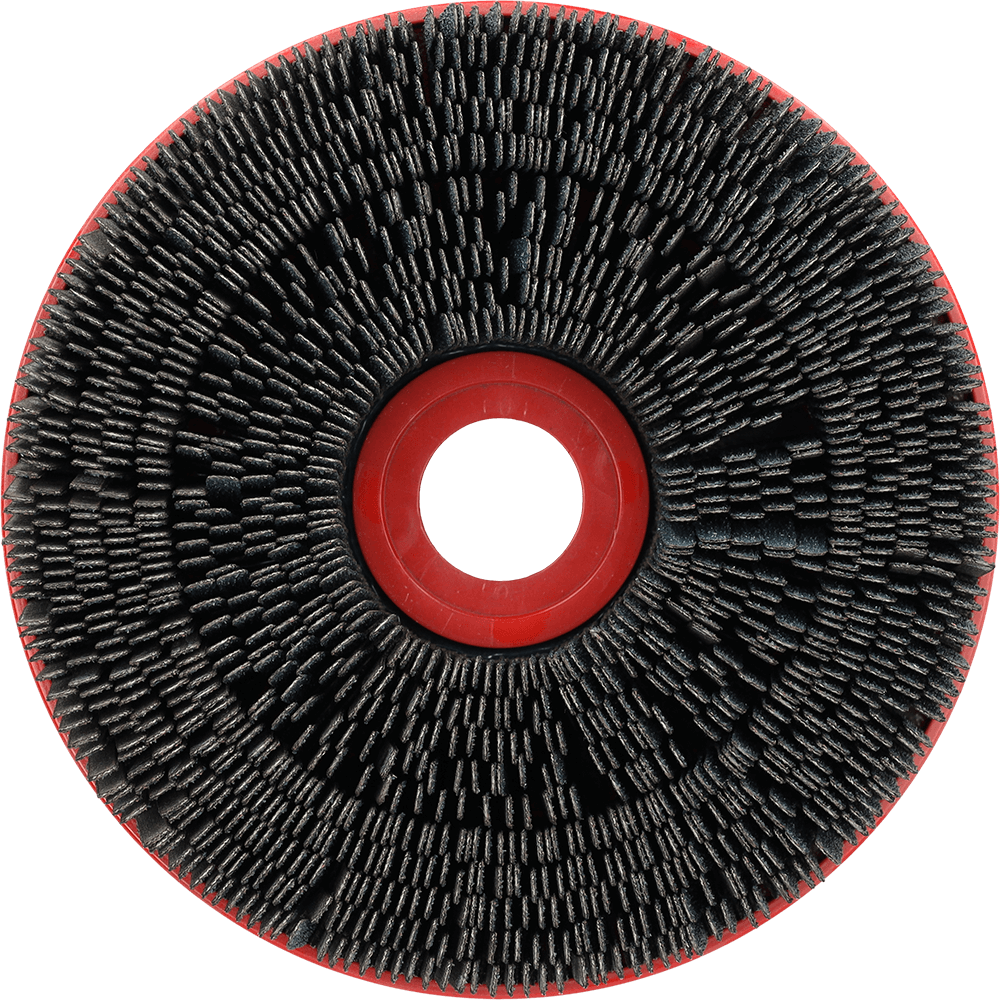

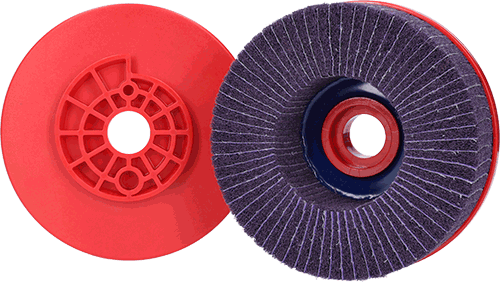

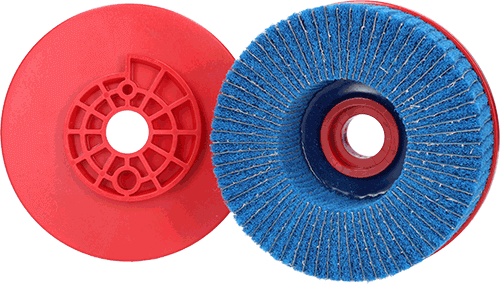

The HERO deburring discs, however, are exclusively made of laser-cut abrasive cloth flaps with a unique finger-like structure. The staggered arrangement of these specialized flaps ensures significantly higher fabric density along with exceptional flexibility, enabling extreme edge rounding and maximum feed speeds.

Need help selecting the deburring disc best suited to your process? Contact us, and our experts will be happy to assist you.

Standard, professional, or HERO?

Boeck deburring discs come in three editions, ensuring you find the right tool for your requirements. The STANDARD deburring discs feature a single-row rim. In contrast, the PROFESSIONAL deburring discs have a double-row abrasive coating, offering a larger contact surface, more active abrasive flaps, and a balanced contact pressure ratio achieved by balancing the outer and inner ring. Both the STANDARD and PROFESSIONAL versions include a combination of cloth and non-woven abrasive flaps.

On the other hand, HERO deburring discs consist exclusively of laser-cut abrasive cloth flaps with a finger-like structure. The staggered arrangement of these special fabric flaps provides significantly higher fabric density combined with high flexibility, enabling extreme edge rounding and maximum feed speeds.

Need more advice on which deburring disc is best suited to your process? Contact us, and our experts will help you make the right choice.

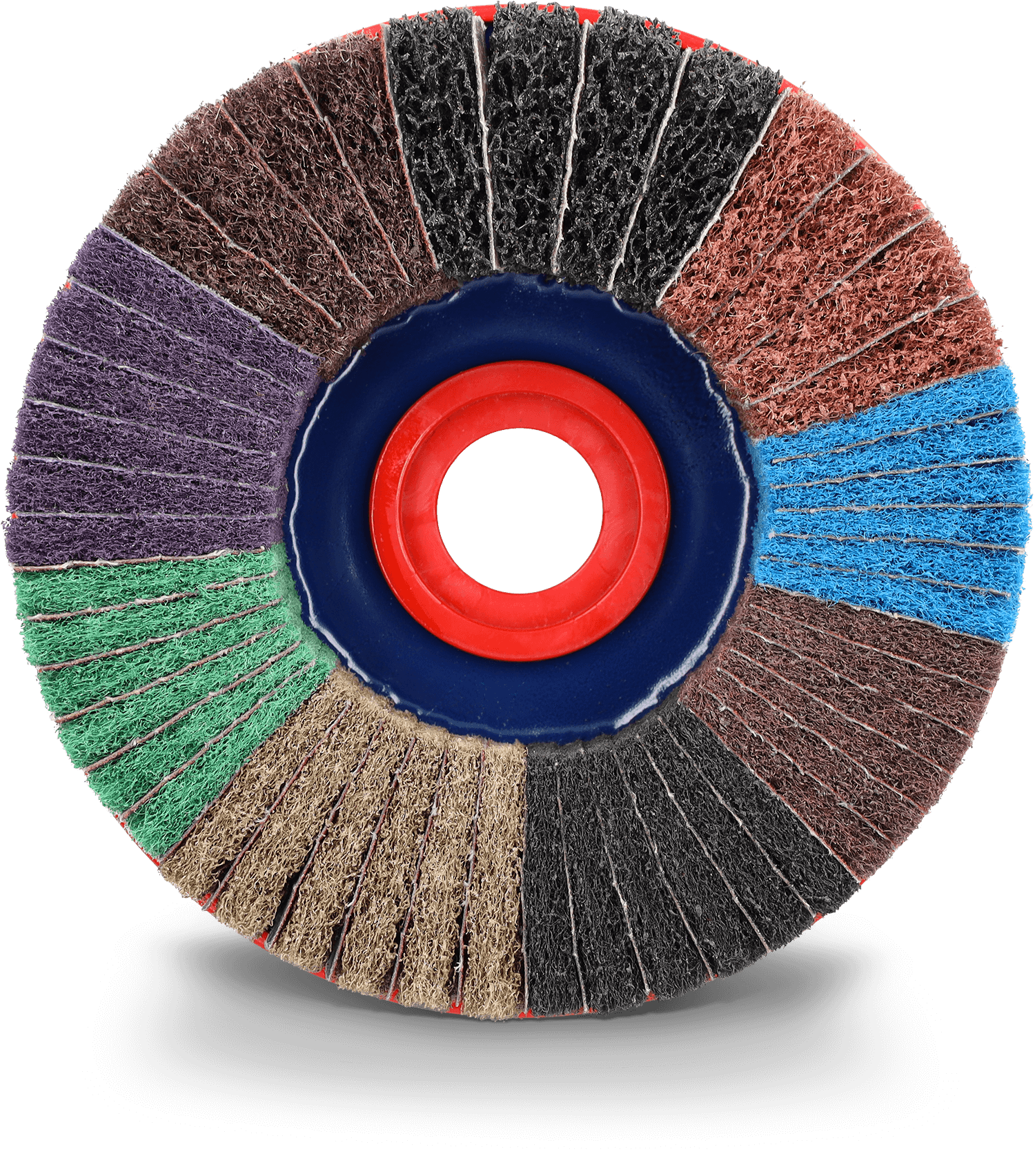

DEBURRING DISC EDITIONS

DARK BROWN EDITION

PURPLE EDITION

GREEN EDITION

GOLD EDITION

RED EDITION

BLUE EDITION

GREY EDITION

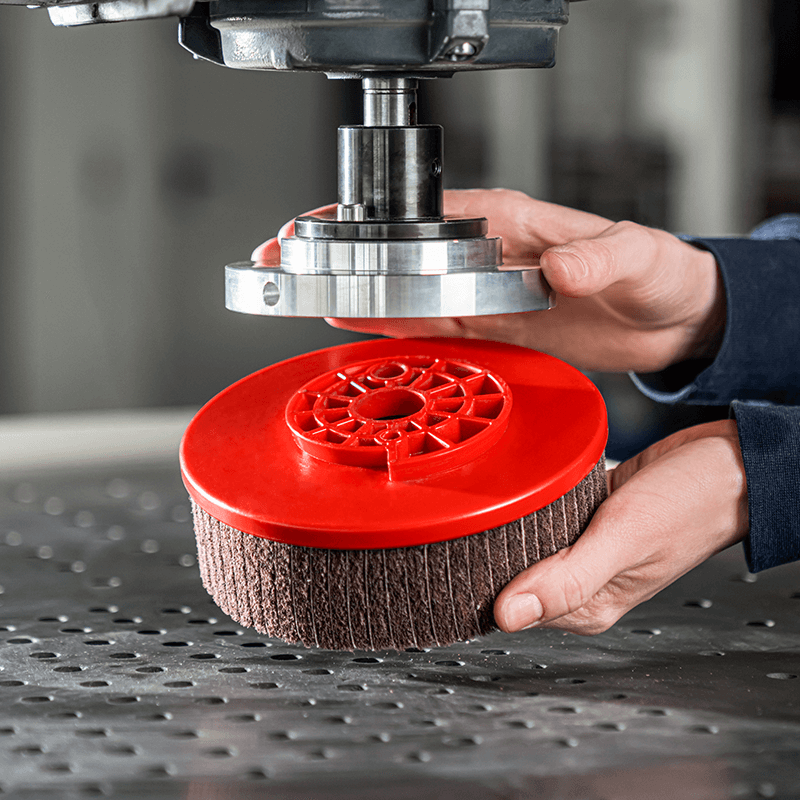

deburring discs – change like a pro

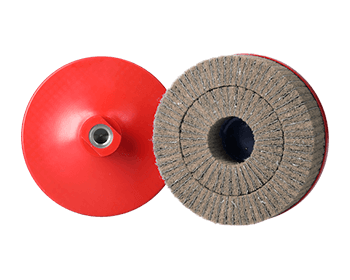

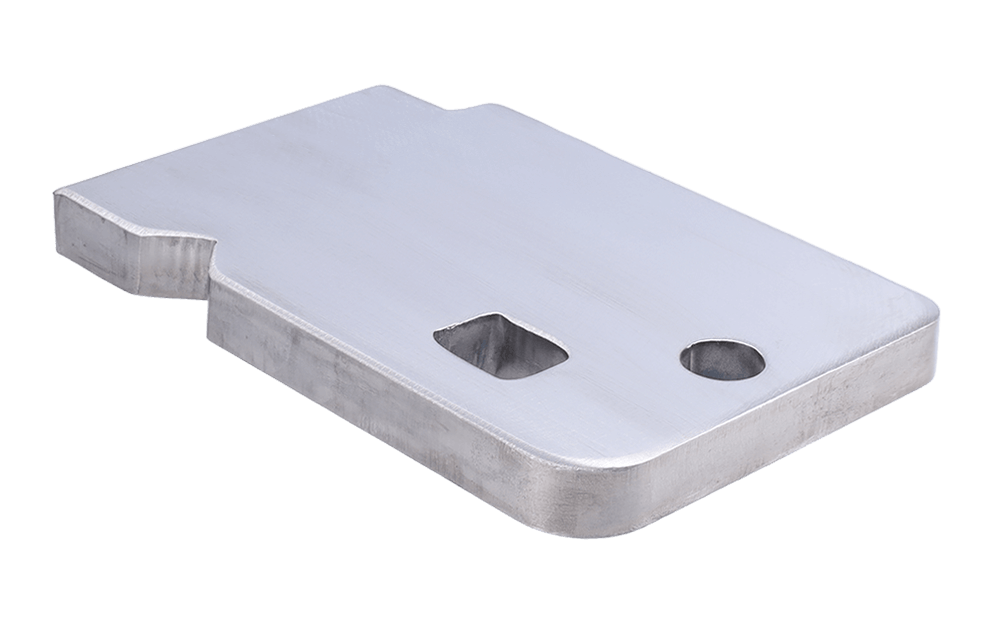

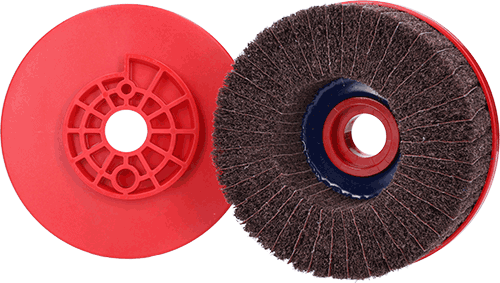

Our deburring discs are available with the QUICK release fastener. The QUICK release fastener is simple to use and eliminates the need for screws or bolts. This allows you to attach the deburring disc to your machine quickly and effortlessly, ensuring the best possible cost-benefit ratio.

To adapt the system to your machine, we offer adapters with various mounts, such as M8, M12, or M14. Need more information about setting up the QUICK system with deburring discs for your machine? Contact us—we’ll be happy to provide you with comprehensive advice.

BOECK DEBURRING DISC ADVANTAGES

Saving processing time

Reduce processing times and make your process more cost-effective by switching to deburring discs customized to your needs.

KNOW-HOW AND ADVICE

Our customers benefit from our strong advisory and application expertise. This know-how ensures optimum competitiveness based on maximum performance processes in every production facility.

Optimization of the deburring process

Our mission is optimizing the entire process chain, from slag removal to finish grinding. We apply the latest know-how and production technologies to our deburring discs.

OUR PRODUCTS ARE COMPATIBLE WITH MOST MACHINE MANUFACTURERS

Arku | Authentec | Boere | Bütfering | Costa | DMC | EMC | Ernst | Famak | Finishline | Fladder® | Gecam | Heesemann | Houfek | Jonsen | Kuhlmeyer | Lissmac | Loeser | Loewer | Madora | Mc Talleres | Metalbrus | Midwest | Ming Ping | Murata | Niederberger | NS Máquinas | Peitzmeier | Pola e massa | Q-Fin | RWT | Salida | St. Link | Telefoncular | Timesavers | Tripuris | VG Machines | Viet | Weber | Wöhler | Wolters

the newest technologies

boeck GmbH develops and manufactures cutting-edge technologies for sheet metal processing. Tool development is driven by both the requirements of our customers and our own foundational testing. This approach allows us to gain a deep understanding of the influencing factors and their interactions within the sheet metal working process, which we translate into effective solutions. As a result, you benefit from tools that are perfectly tailored to your needs, as well as from our expertise in optimal process parameters.

Our deburring discs are MADE IN GERMANY by highly qualified personnel using the latest, highly integrated machining technologies. In terms of production goals, we achieve maximum efficiency, particularly through automation and the continuous digitalization of administrative and technical processes.

We work tirelessly to ensure that our customers receive the highest quality and most effective deburring discs, customized and delivered in the shortest possible time.

Deburring discs in action

YOUR CONTACT PERSONS

MARC BÖCK

Dipl.-Ing. (FH) Dipl.-Kfm. (FH)

CEO

ERICH LIEDEL

Dipl.-Ing. (FH)

Plant manager