OXIDE REMOVAL WITH TOOLS BY BOECK

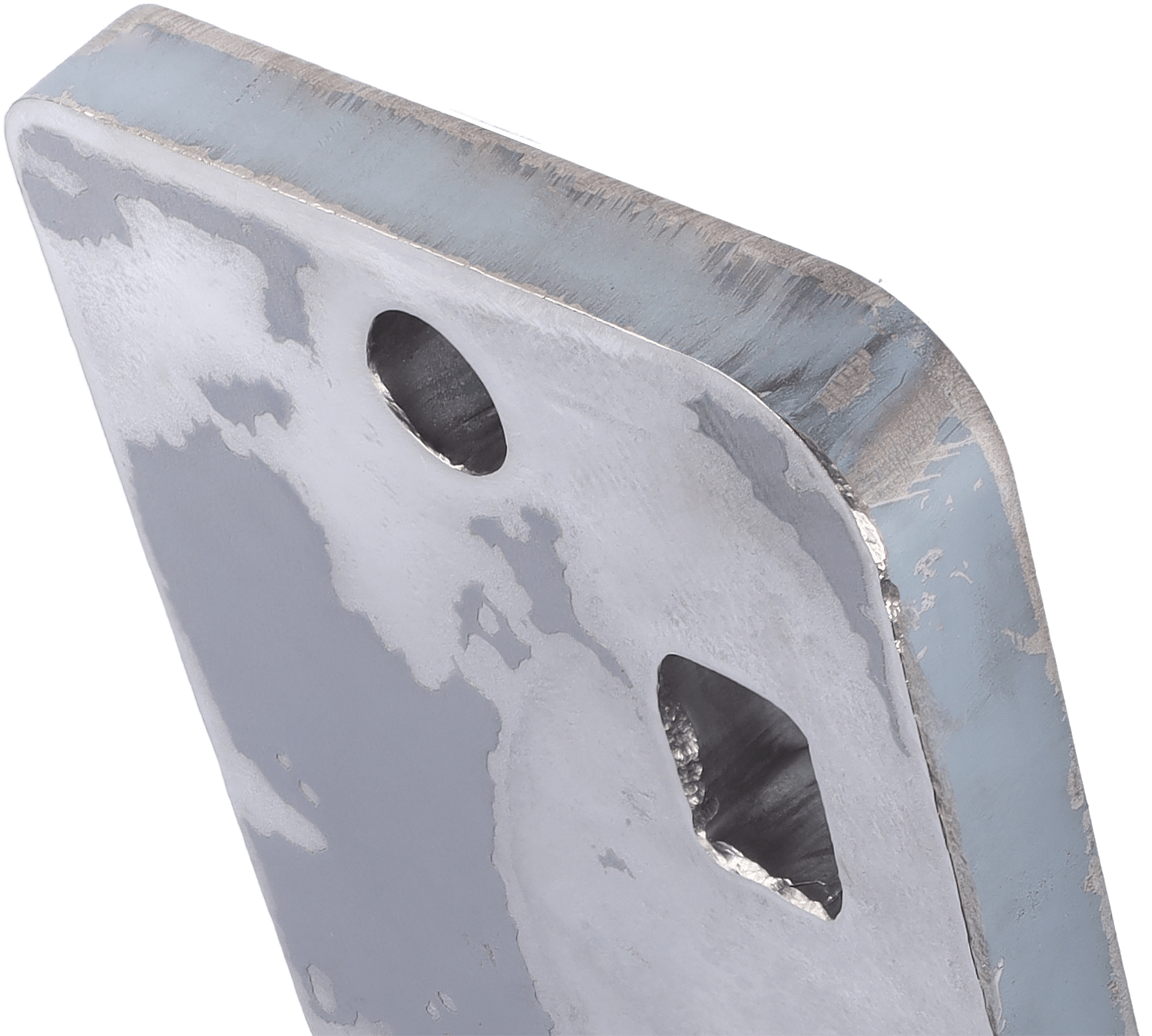

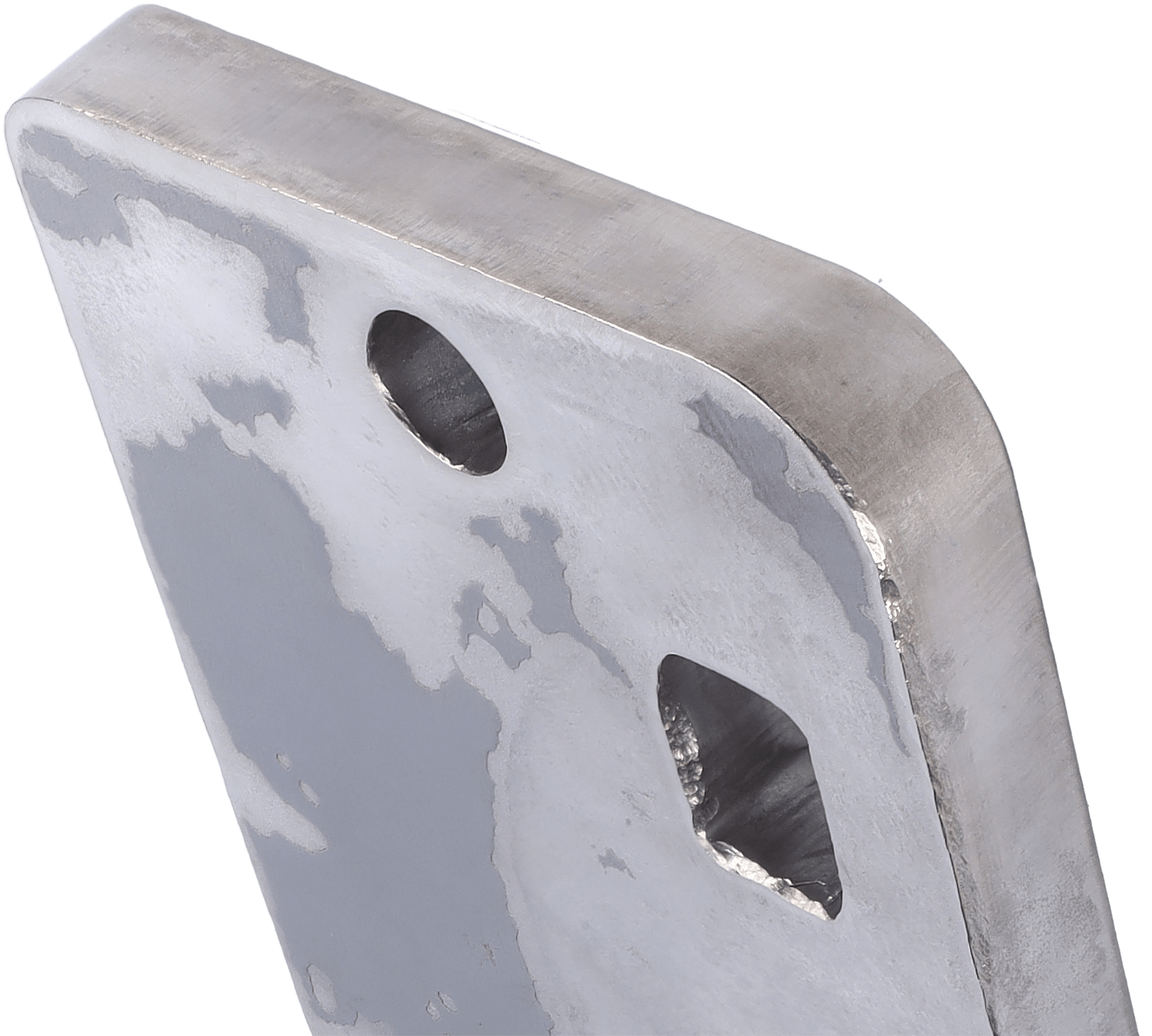

When metal sheets are cut with oxygen, a dark, bluish oxide layer remains. This layer must be removed before further processing. To meet this need, we offer the ideal tool solutions for efficient oxide removal.

OXIDE REMOVAL

When oxygen is used during the sheet metal cutting process, a dark, bluish oxide layer forms along the edges. This layer can lead to several issues in subsequent processing steps. For example, coatings may fail to adhere properly and flake off, while welds may lack durability and corrode prematurely. To ensure efficient and cost-effective further processing, this oxide layer must be removed.

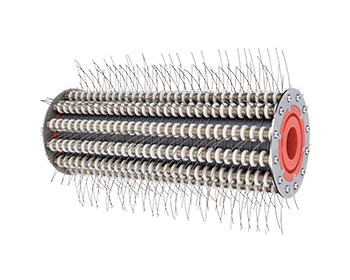

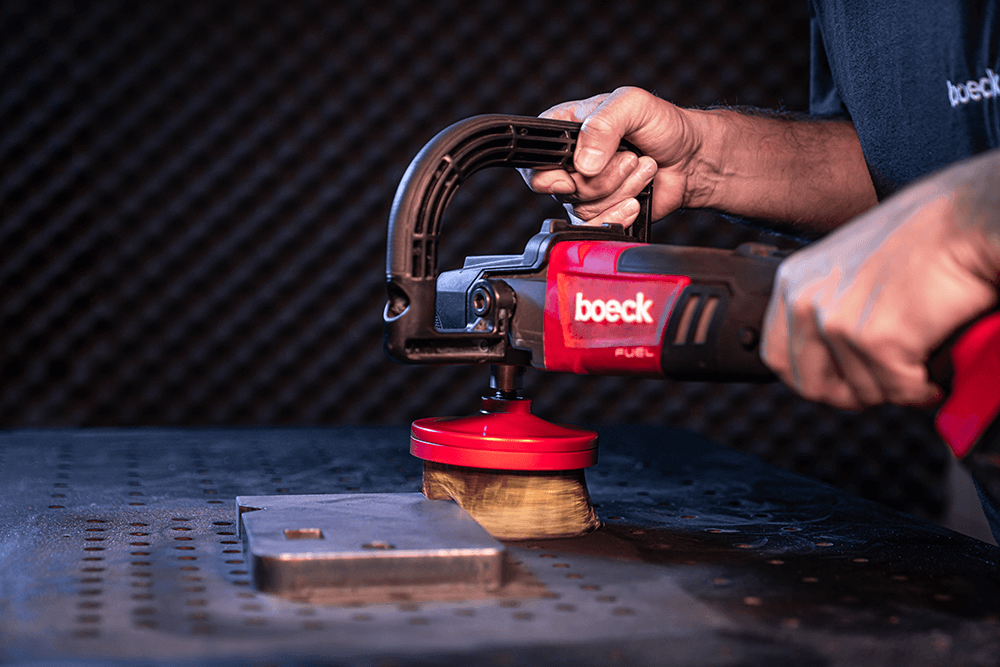

At boeck, we remove oxide mechanically using wire brushes and wheels. While chemical methods can also be used, they are less ideal as they may damage thinner sheet metal and require additional processing steps. In contrast, oxide removal wires gently scrape away the oxide layer, preserving the underlying material and removing only the excess.

OUR TOOLS FOR REMOVING OXIDE

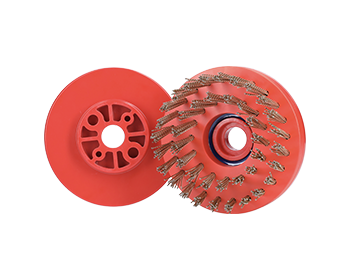

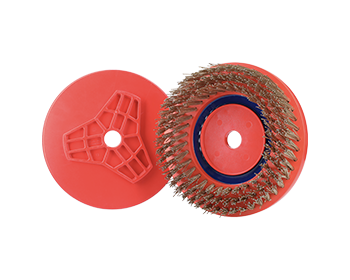

ADJUSTABLE OXIDE WHEELS

Oxide removal is now more efficient than ever! Our adaptable oxide wheels can be adjusted in diameter by up to 25% in just seconds.

When using both deburring wheels and oxide wheels simultaneously, uneven wear can reduce productivity. With our new variable oxide roller, you can synchronize the infeed with the deburring wheel, enabling you to remove the oxide layer and round edges simultaneously—without significant setup time losses.

Tailored Tools for Effective Oxide Removal – Expert Advice at Your Service

Whether you’re using a handheld machine or an automated deburring system, we provide tools tailored to your process. Additionally, we offer a wide selection of oxide brushes and wheels in various sizes and mounts to meet your specific needs.

If you need assistance selecting the optimal tool for your oxide removal process, feel free to contact us—we’ll gladly provide expert advice.

OUR PRODUCTS ARE COMPATIBLE WITH MOST MACHINE MANUFACTURERS

Arku | Authentec | Boere | Bütfering | Costa | DMC | EMC | Ernst | Famak | Finishline | Fladder® | Gecam | Heesemann | Houfek | Jonsen | Kuhlmeyer | Lissmac | Loeser | Loewer | Madora | Mc Talleres | Metalbrus | Midwest | Ming Ping | Murata | Niederberger | NS Máquinas | Peitzmeier | Pola e massa | Q-Fin | RWT | Salida | St. Link | Telefoncular | Timesavers | Tripuris | VG Machines | Viet | Weber | Wöhler | Wolters

OUR CUSTOMERS' BENEFITS

Saving processing time

Reduce processing times and make your process more cost-effective by switching to oxide removal tools customized to your needs.

Ensuring safety

Reduce labor intensity, ergonomic strains and other hazards by omitting manual oxide removal or heavy chemical use.

Optimization of thE removal process

We optimize the entire process chain, from oxide removal to finish grinding, using cutting-edge expertise and the latest production technologies.

oxide removal brushes in action

the newest oxide removal technologies

Boeck GmbH develops and manufactures advanced technologies for sheet metal processing, including oxide removal. Our tool development is driven by customer requirements and rigorous in-house testing. This dual approach enables us to deeply understand the factors influencing the sheet metal processing chain and their interactions, translating this knowledge into effective solutions. The result? Tools perfectly tailored to your needs, complemented by expert guidance on optimal process parameters.

All our tools are proudly MADE IN GERMANY, crafted by highly skilled professionals using state-of-the-art, fully integrated machining technologies. We ensure maximum production efficiency through automation and the continuous digitalization of administrative and technical processes.

At Boeck, we are committed to delivering the highest-quality tools, customized to your specific requirements, with the shortest lead times possible.

YOUR CONTACT PERSONS

MARC BÖCK

Dipl.-Ing. (FH) Dipl.-Kfm. (FH)

CEO

ANJA BERSCHEIT

M.Sc.

Head of automation & quality