PRE-GRINDING WITH TOOLS BY BOECK

During pre-grinding, primary burrs and unevenness are removed from the surface to create a perfect basis for further processing, minimize the risk of injury and ensure a better appearance. No matter what machine or material you are working with, boeck manufactures unique tools for your pre-grinding process.

PRE-GRINDING AND DEBURRING

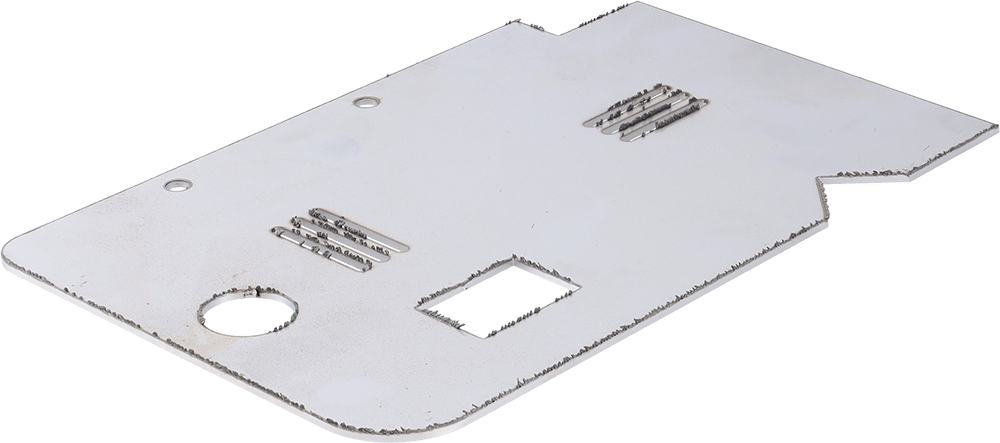

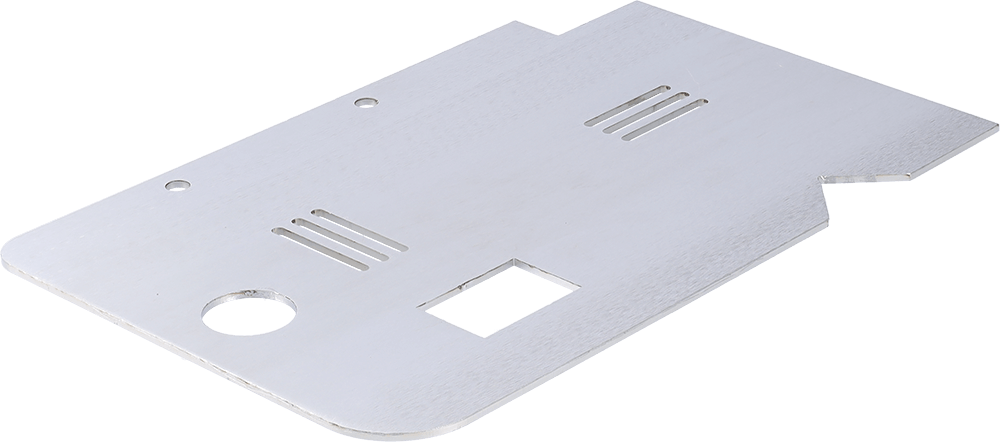

Burr formation is often unavoidable on laser-, plasma-, and oxyfuel-cut or stamped sheet metal parts. Other undesirable side effects on sheet metal include spatter on the surface, unevenness, or scaling.

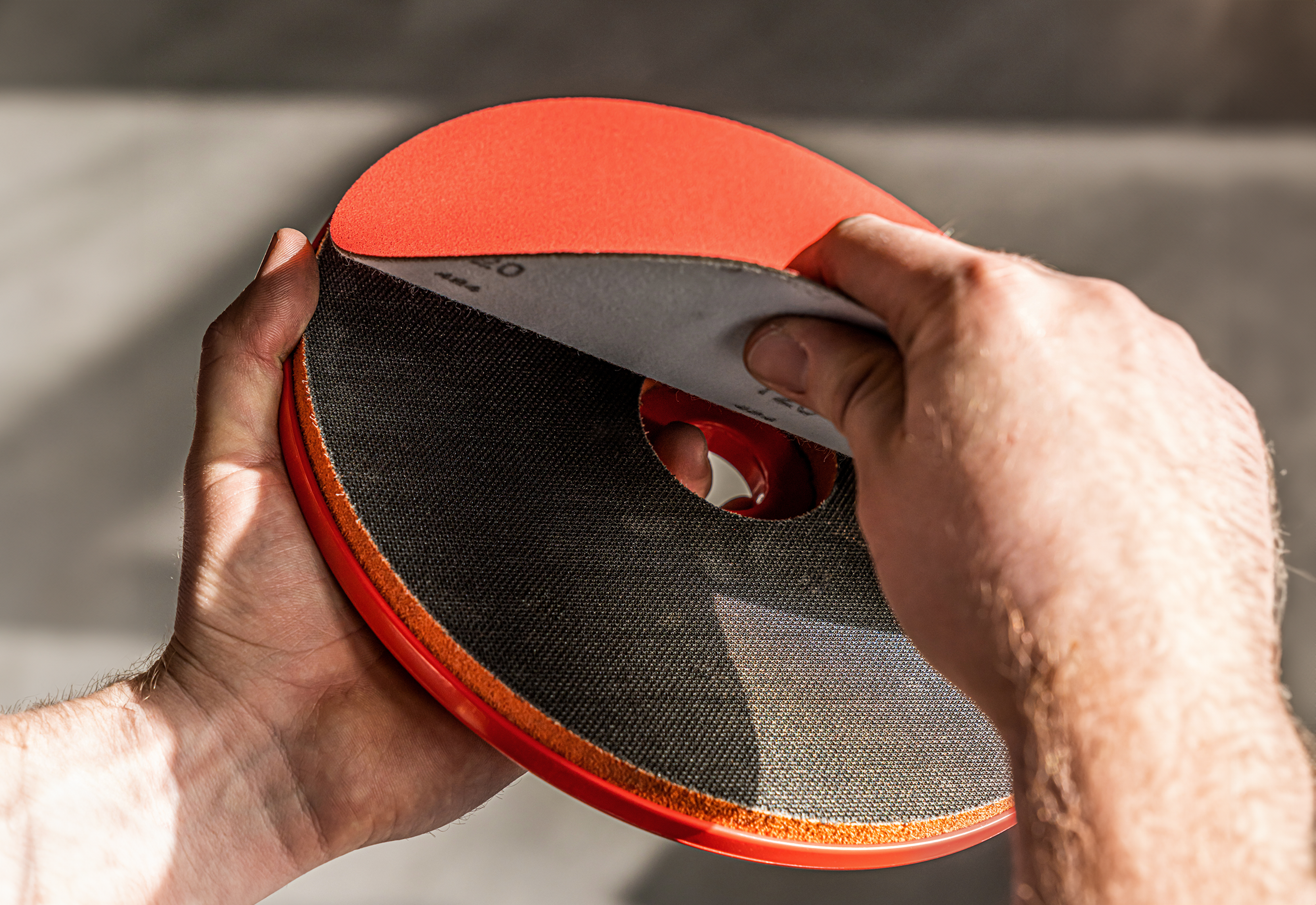

Pre-grinding to remove these imperfections can be performed in various ways using different machine types. Pre-grinding with abrasive belts or velcro foam pads combined with velcro abrasive discs typically removes burrs from sheet metal parts. For more gentle pre-grinding and very light burrs, products like non-woven surface conditioning discs are ideal.

OUR TOOLS FOR PRE-GRINDING AND DEBURRING

Abrasive Cloth Belts for Efficient Sheet Metal Processing

Abrasive cloth belts are used for pre-grinding sheet metal components and in particular for primary burr removal, primarily in grit sizes 80 and 120. The abrasive belts are usually used in grit 180 and finer for finish grinding of sheet metals. Depending on the material and the desired surface properties, we will gladly advise you which abrasive belt is most suitable for your process.

Choosing the Right Abrasive for Your Workpiece

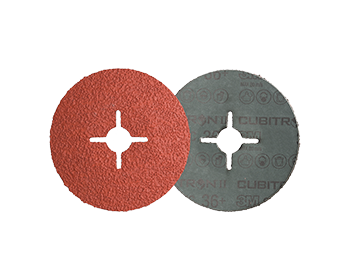

Depending on the requirements of your workpiece—such as material, sheet thickness, and burr thickness—different abrasives are used. These include aluminum oxide, silicon carbide, ceramic grain, Cubitron II, zirconium alumina, and many more! The various tool editions are color-coded, and the wide range of combinations of tool types and facing materials can meet almost any requirement.

Need help selecting the right abrasive for your metal sheets? Contact us—we’ll be happy to advise you!

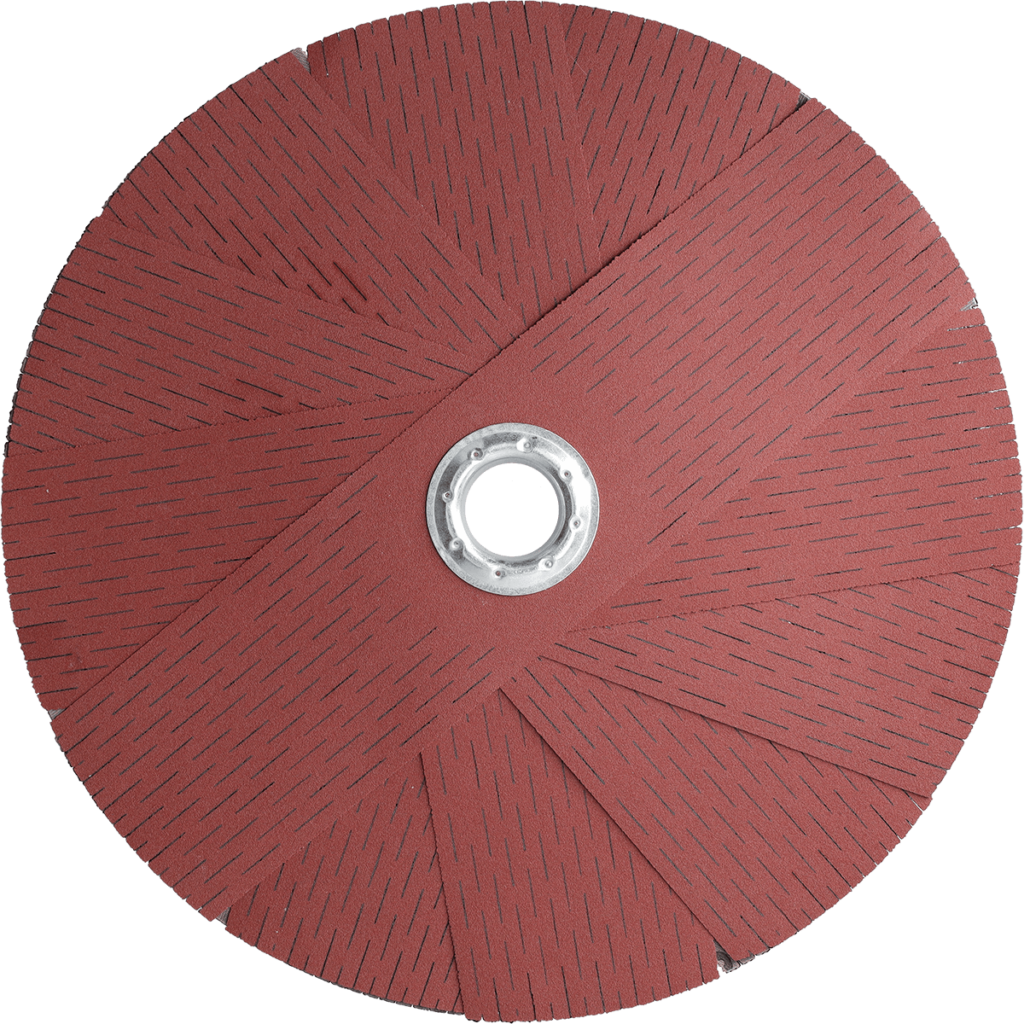

Abrasive Discs for Pre-Grinding and Light Deburring

Abrasive discs are essential for pre-grinding sheet metal components, light deburring, and achieving a smooth finish. Depending on the burr size, material type, and desired stock removal rate, our experts are ready to advise you on selecting the most suitable abrasive cloth sheets to optimize your process.

PRE-GRINDING TUBES AND PROFILES WITH SANDING STARS

For pre-grinding, deburring, and edge rounding of tubes and profiles, we recommend our sanding stars. Available in various mounts and sizes, they are compatible with a wide range of angle grinders and tube deburring machines.

OUR PRODUCTS ARE COMPATIBLE WITH MOST MACHINE MANUFACTURERS

Arku | Authentec | Boere | Bütfering | Costa | DMC | EMC | Ernst | Famak | Finishline | Fladder® | Gecam | Heesemann | Houfek | Jonsen | Kuhlmeyer | Lissmac | Loeser | Loewer | Madora | Mc Talleres | Metalbrus | Midwest | Ming Ping | Murata | Niederberger | NS Máquinas | Peitzmeier | Pola e massa | Q-Fin | RWT | Salida | St. Link | Telefoncular | Timesavers | Tripuris | VG Machines | Viet | Weber | Wöhler | Wolters

the newest pre-grinding technologies

boeck GmbH develops and manufactures cutting-edge technologies for sheet metal processing, including pre-grinding. Tool development is driven both by our customers’ requirements and by our own foundational testing. This approach allows us to build a deep understanding of the influencing factors and their interactions within the sheet metal working process, which we translate into effective solutions. This ensures that you benefit from tools perfectly tailored to your needs, along with expertise in optimal process parameters.

Our tools are MADE IN GERMANY by highly qualified personnel, utilizing the latest, highly integrated machining technologies. We achieve maximum efficiency in meeting production objectives, particularly through the automation and seamless digitization of administrative and technical processes.

We work tirelessly to ensure that our customers receive the highest quality and most effective pre-grinding tools, customized and delivered in the shortest possible time.

pre-grinding in action ON VARIOUS MACHINES

OUR CUSTOMERS' SUCCESS

Saving processing time

Reduce processing times and make your process more cost-effective by switching to pre-grinding tools customized to your needs.

KNOW-HOW AND ADVICE

Our customers benefit from our strong advisory and application expertise. This know-how ensures optimum competitiveness based on maximum performance processes in every production facility.

Optimization of the pre-grinding process

Our mission is optimizing the entire process chain, from slag removal and pre-grinding to finish grinding. We apply the latest know-how and production technologies to our tools.

YOUR CONTACT PERSONS

MARC BÖCK

Dipl.-Ing. (FH) Dipl.-Kfm. (FH)

CEO

ANJA BERSCHEIT

M.Sc.

Head of automation & quality