SLAG REMOVAL WITH TOOLS BY BOECK

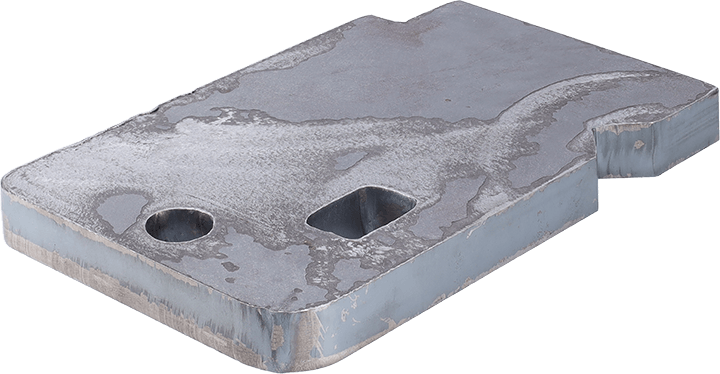

In sheet metal processing, the slag removal step is of essential importance. Slag is an undesirable by-product of plasma and oxy-fuel cutting. With the slag hammer brushes from boeck, you can remove even the most stubborn slag from your workpieces.

METAL SLAG REMOVAL

During plasma or gas cutting, strong melting often occurs, with the molten metal sagging on the beam-exit side. This so-called slag or dross occurs both on the inner and outer contours of the workpiece and must be removed for effective and economical further processing.

Common manual methods for slag removal include chipping it away using a hammer and chisel, or grinding using an angle grinder. However, this is labor intensive and leads to longer overall processing times.

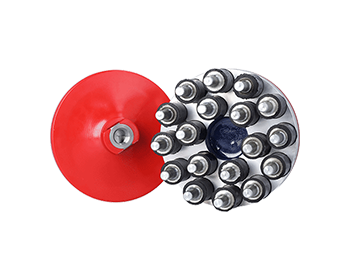

In terms of mechanical processes, slag can be removed by grinding with a soft contact roller. An even faster and easier industrial method is knocking it off using a deslagging brush made up of multiple flexibly mounted steel pins.

Hammer and Chisel

- Precise

- Labor intensive – risk of strain and injury

- Slow – long processing times

Angle grinder

- Imprecise – risk of removing too much material

- Labor intensive

- Relatively quick

Deslagging brushes

- Precise – removes excess material only

- Not labor intensive – safest processing

- Very quick – shortest processing times

Efficient slag removal

Use the boeck slag hammer brushes for effective removal of unwanted slag residues. They are available for all common deburring machine types, whether angle grinders/polishers or automatic machines.

Depending on the material and toughness of the slag, it can be useful to switch between different degrees of pin hardness. There are four variants to choose from in a wide range of diameters.

Do you need help selecting the optimum tool for removing slag from your components? Please contact us. We will be happy to advise you.

OUR PRODUCTS ARE COMPATIBLE WITH MOST MACHINE MANUFACTURERS

Arku | Authentec | Boere | Bütfering | Costa | DMC | EMC | Ernst | Famak | Finishline | Fladder® | Gecam | Heesemann | Houfek | Jonsen | Kuhlmeyer | Lissmac | Loeser | Loewer | Madora | Mc Talleres | Metalbrus | Midwest | Ming Ping | Murata | Niederberger | NS Máquinas | Peitzmeier | Pola e massa | Q-Fin | RWT | Salida | St. Link | Telefoncular | Timesavers | Tripuris | VG Machines | Viet | Weber | Wöhler | Wolters

OUR CUSTOMERS' BENEFITS

Saving processing time

Reduce processing times and make your process more cost-effective by switching to deslagging tools customized to your needs.

Ensuring safety

Reduce labor intensity, ergonomic strains and other deslagging hazards by omitting manual hammering or grinding.

Optimization of the deslagging process

Our mission is optimizing the entire process chain, from slag removal to finish grinding. We apply the latest know-how and production technologies to our tools.

deslagging brushes in action

the newest deslagging technologies

boeck GmbH develops and manufactures the latest technologies for sheet metal processing, including slag removal. On the one hand, tool development takes place on the basis of the requirements of our customers and, on the other hand, we perform basic tests. This way, we develop a deep knowledge of the influencing factors and their interactions within the sheet metal working process and translate this into solutions. This ensures you will benefit from tools that are perfectly tailored to your needs, as well as from know-how in terms of optimal process parameters. Our tools are MADE IN GERMANY by highly qualified personnel and the use of the latest, highly integrated machining technologies. In terms of production objectives, we achieve maximum efficiency, particularly through the automation and continuous digitization of administrative and technical processes.

We work tirelessly to ensure that our customers benefit from the best quality and most effective tools possible, customized in the shortest time.

YOUR CONTACT PERSONS

MARC BÖCK

Dipl.-Ing. (FH) Dipl.-Kfm. (FH)

CEO

ANJA BERSCHEIT

M.Sc.

Head of automation & quality